In today’s data-driven world, two-dimensional barcodes have become ubiquitous tools for storing and sharing information quickly and efficiently. Among the most prominent 2D barcode formats are Data Matrix codes and QR (Quick Response) codes. While both serve similar fundamental purposes, they possess distinct characteristics that make them suitable for different applications and industries.

Understanding the Basics

Data Matrix codes are square or rectangular matrix barcodes consisting of black and white cells arranged in a grid pattern. Developed by International Data Matrix in the 1980s and later standardized as ISO/IEC 16022, these codes can store up to 2,335 alphanumeric characters or 3,116 numeric characters. The format includes built-in error correction capabilities and can be read even when partially damaged.

QR codes, created by Denso Wave in 1994, are square-shaped barcodes featuring distinctive position markers in three corners. Standardized as ISO/IEC 18004, QR codes can hold up to 4,296 alphanumeric characters or 7,089 numeric digits. They were specifically designed for rapid scanning and decoding, with “Quick Response” literally embedded in their name.

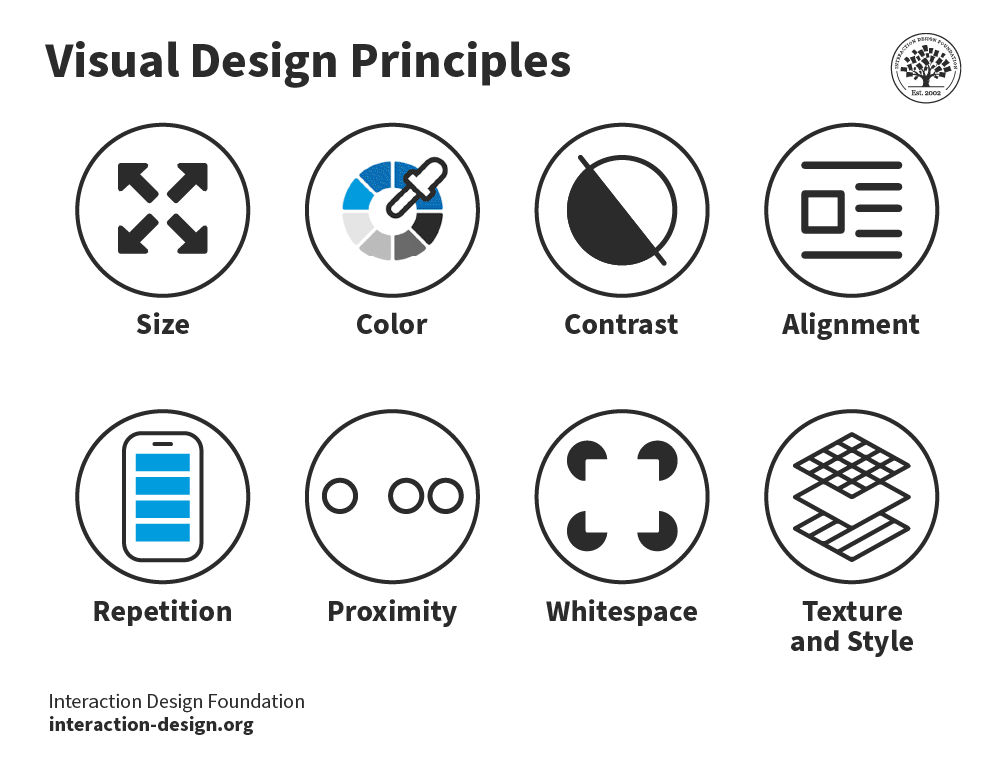

Visual Design and Structure

The most immediately apparent difference lies in their visual appearance. Data Matrix codes present a clean, uniform grid without any prominent landmark features, relying on a solid border along two adjacent sides (typically the bottom and right edges) for orientation. This minimalist design allows for extremely compact sizing while maintaining readability.

QR codes, conversely, feature three large square position markers in their corners, along with smaller alignment patterns and timing patterns throughout the code. These visual elements make QR codes instantly recognizable and enable rapid detection by scanning devices, even when viewed at various angles or distances.

Size and Space Efficiency

Data Matrix codes excel in applications where space is at a premium. They can be printed as small as 0.3mm per cell while remaining readable, making them ideal for marking tiny components or products where real estate is limited. The format’s efficient data encoding allows more information to be stored in smaller spaces compared to QR codes.

QR codes, while generally larger than Data Matrix codes for equivalent data storage, offer superior scanning reliability in consumer applications. Their size makes them easier to scan with smartphone cameras, and the position markers facilitate quick recognition and orientation correction.

Error Correction and Durability

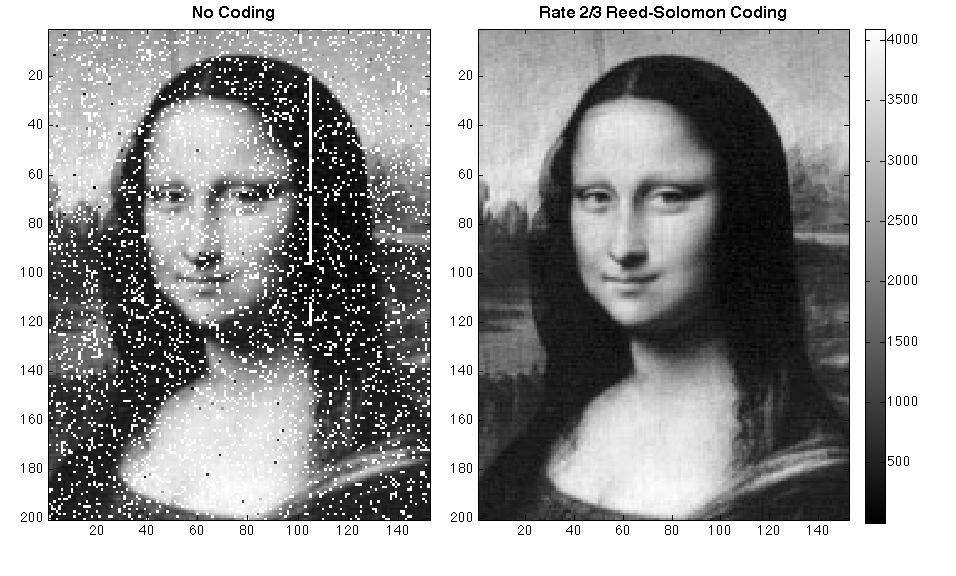

Both formats incorporate sophisticated error correction mechanisms, but with different approaches. Data Matrix codes use Reed-Solomon error correction, allowing them to remain readable even when up to 25% of the code is damaged or obscured. This resilience makes them particularly valuable in industrial environments where codes may be subject to wear, contamination, or partial obstruction.

QR codes also employ Reed-Solomon error correction but offer four different levels of correction (L, M, Q, H), ranging from 7% to 30% recovery capability. Users can select the appropriate level based on their specific application requirements, balancing data capacity against error resilience.

Industry Applications and Use Cases

Data Matrix codes dominate in industrial and healthcare applications. They’re extensively used for product tracking in manufacturing, pharmaceutical packaging, aerospace component identification, and medical device labeling. The automotive industry relies heavily on Data Matrix codes for parts traceability throughout the supply chain. Their ability to maintain readability on curved surfaces and in challenging environmental conditions makes them indispensable in these sectors.

QR codes have found their niche primarily in consumer-facing applications. They’re prevalent in marketing campaigns, restaurant menus, event ticketing, mobile payments, and social media integration. The COVID-19 pandemic significantly accelerated QR code adoption for contactless interactions, from digital menus to health pass verification.

Scanning and Compatibility

The scanning ecosystem differs considerably between the two formats. Data Matrix codes typically require specialized industrial scanners or dedicated mobile applications, as they’re not natively supported by most smartphone camera applications. However, industrial scanning equipment reads Data Matrix codes with exceptional speed and accuracy.

QR codes benefit from widespread native support in smartphone cameras and countless mobile applications. Most modern smartphones can scan QR codes directly through their camera apps without requiring additional software, contributing to their popularity in consumer applications.

Data Capacity and Encoding

While both formats can store substantial amounts of data, their optimal use cases differ. Data Matrix codes are particularly efficient for storing shorter strings of data, making them ideal for serial numbers, batch codes, and tracking identifiers. Their encoding efficiency shines when dealing with numeric and alphanumeric data commonly used in industrial applications.

QR codes offer greater overall data capacity and more flexible encoding options, including support for different character sets and data types. This versatility makes them suitable for storing URLs, contact information, WiFi credentials, and other consumer-oriented data types.

Security Considerations

Neither format inherently provides encryption or security features, but both can be integrated into secure systems. Data Matrix codes are often used in regulated industries where traceability and authenticity are critical, while QR codes in consumer applications should be approached with caution, as malicious codes can direct users to harmful websites or trigger unwanted actions.

Making the Right Choice

The selection between Data Matrix and QR codes ultimately depends on the specific application requirements. Data Matrix codes are superior for industrial applications requiring small size, high durability, and reliable performance in challenging environments. QR codes excel in consumer applications where ease of scanning, widespread compatibility, and larger data capacity are priorities.

Understanding these fundamental differences enables organizations to select the most appropriate 2D barcode format for their specific needs, ensuring optimal performance and user experience in their particular use case.